Aloha Bay

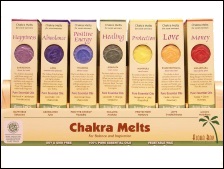

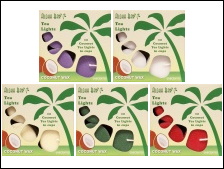

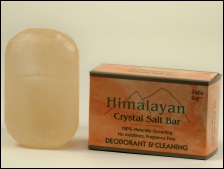

Aloha! For thirty years, Aloha Bay has been helping retailers and individuals find sustainable home décor and spa products for their customers and families. Our eco-friendly candles and Himalayan salt products are made from the finest natural ingredients in an artful design of perfect proportion and beauty. Around the world, Aloha Bay supports farmers, craftspersons, and other workers in earning a living income. This helps maintain cultural and traditional lifestyles into the future while creating lasting relationships with the local and global communities that we serve.

Around the world, Aloha Bay supports farmers, craftspersons, and other workers in earning a living income. This helps maintain cultural and traditional lifestyles into the future while creating lasting relationships with the local and global communities that we serve.

Aloha Bay is a member of the World Fair Trade Organization (WFTO) which guarantees that Aloha Bay is in compliance with the WFTO global Fair Trade Principles and the WFTO Fair Trade Standard.

To place an order, browse our menu on the left or the pictured categories below. Retailers, please visit our wholesale page.

Aloha! For thirty years, Aloha Bay has been helping retailers and individuals find sustainable home décor and spa products for their customers and families. Our eco-friendly candles and Himalayan salt products are made from the finest natural ingredients in an artful design of perfect proportion and beauty.

Around the world, Aloha Bay supports farmers, craftspersons, and other workers in earning a living income. This helps maintain cultural and traditional lifestyles into the future while creating lasting relationships with the local and global communities that we serve. Aloha Bay is a member of the World Fair Trade Organization (WFTO) which guarantees that Aloha Bay is in compliance with the WFTO global Fair Trade Principles and the WFTO Fair Trade Standard.

Aloha Bay is a member of the World Fair Trade Organization (WFTO) which guarantees that Aloha Bay is in compliance with the WFTO global Fair Trade Principles and the WFTO Fair Trade Standard.

Browse our product menu to place an order. Retailers, please visit our wholesale page. Also be sure to check out our monthly specials and new products.